It’s no secret that technology has been evolving at light speed in the past few decades. If you need proof, just look at the development of computer and phone technology in the last ten years. The next big wave of manufacturing technology — as part of the fourth industrial revolution — is known as “Industry 4.0.”

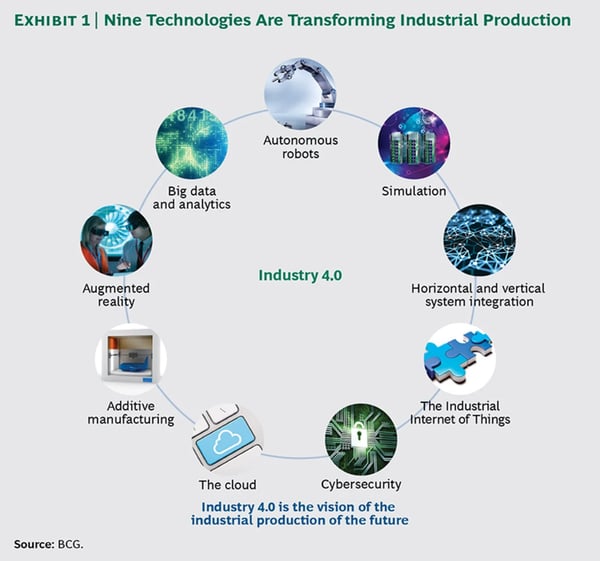

What is Industry 4.0?Industry 4.0 is a new wave of manufacturing technology as part of the fourth industrial revolution, which includes technologies such as the Internet of Things, autonomous robots, etc. |

History Leading Up to Industry 4.0

Manufacturing has been a developing process throughout history. The first industrial revolution began in the 18th century, when mechanization, water power and steam power first came into play, which industrialized tasks once accomplished by hand and made way for the modern factory1. The second industrial revolution began in the 20th century, and included the advent of the assembly line and mass production. This led up to the current industrial era, the third industrial revolution, which utilizes computers for purposes of automation and programming to help simplify and increase the efficiency of production.

The Fourth Industrial Revolution (Industry 4.0)

We are currently on the cusp of the fourth industrial revolution. Industry 4.0 builds on the technology introduced in the third industrial revolution by utilizing programming and technology to allow computers and robotic technology to operate with less human involvement and increase efficiency. This includes nine transformational technologies, including:

-

Autonomous robots

-

Simulation

-

Horizontal and vertical system integration

-

The industrial Internet of Things

-

Cybersecurity

-

The cloud

-

Additive manufacturing

-

Augmented reality

-

Big data and analytics

The nine transformational technologies of Industry 4.0. Read the complete BCG article here.

The Effect of Industry 4.0 On Human Workers

While Industry 4.0 technologies may replace the need for some blue-collar positions, new technologies will increase the industry’s demand for computer engineers, mechanics, network specialists and more. Manufacturing advocates are encouraging manufacturers to embrace the new Industry 4.0 technologies rather than reject upgrades and technology that will simplify their processes.

In the Maryland Manufacturing Market

Dr. Mike Galiazzo of the Regional Manufacturing Institute (RMI) urges Maryland manufacturers to start planning for and implementing Industry 4.0 technologies sooner rather than later.

“If any or all of these technologies are not in your company’s 'master plan' you need to act now,” Galiazzo says. “The power of 4.0 technologies will create a robust globally competitive manufacturing system putting more American made products on store shelves.”

Galiazzo believes this 20-20 “future” vision of Industry 4.0 technologies will help keep Maryland manufacturers at the forefront of the manufacturing industry.

Need Help?

Contact us online or call 800.899.4623.

1“The third industrial revolution” (The Economist)